Floor 22, Building 1, Xiaoshan Chamber of commerce mansion,No. 185 Jincheng road,Beigan street, Xiaoshan district,Hangzhou city, Zhejiang province, China. wayne@zaianmaterial.com

Floor 22, Building 1, Xiaoshan Chamber of commerce mansion,No. 185 Jincheng road,Beigan street, Xiaoshan district,Hangzhou city, Zhejiang province, China. wayne@zaianmaterial.com

The safety of outdoor decks is directly linked to their anti-slip performance, especially around pools, coastal areas, or in rainy climates where traditional materials often pose slip hazards. PVC decking systems, with their innovative scientific design and rigorous testing standards, have emerged as an ideal solution for wet environments. This article explores the technical logic behind their safety through material engineering and certification benchmarks.

1. The Core of Anti-Slip Performance: Synergistic Design of Material and Texture

The slip resistance of PVC decking stems from its unique composite structure and surface treatment technology:

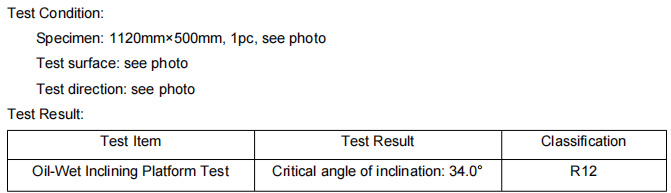

Third-generation deep embossed texture disrupts water film continuity, accelerates drainage, and increases sole contact points to enhance friction. This design achieves the European R12 anti-slip rating (EN 13845), ensuring stability in wet conditions.

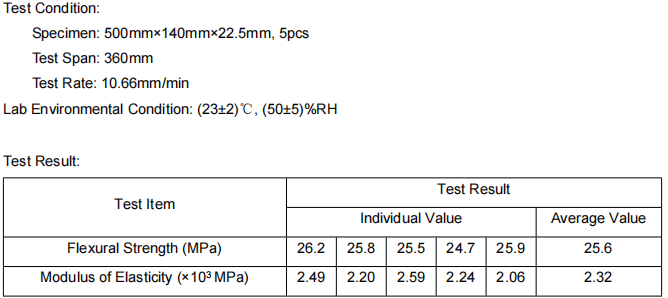

Elastic modulus (2.32×10³ MPa) provides progressive resistance during shifts in body weight. Comparative tests show PVC decking delivers 3.2x higher foot friction than wood on a 15° incline.

ASA coating inhibits algae growth, preventing biofilm-induced slipperiness.

2. Validated by Authority Testing: From Lab to Real-World Scenarios

To quantify anti-slip performance, PVC decking undergoes multiple international standard tests:

(1) Critical Tilt Angle 34° (AS 4586-2013): Exceeds ceramic tiles (28°) and wood (22°) in wet-state testing, maintaining grip even on sloped surfaces.

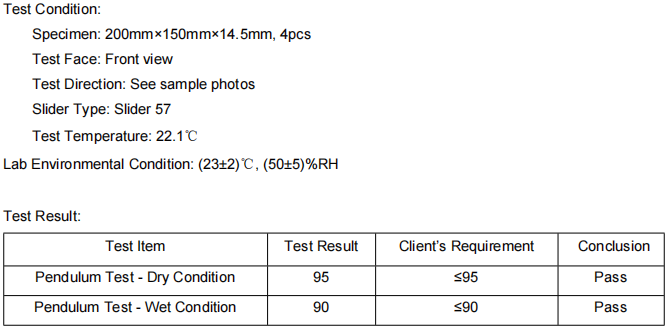

(2) Pendulum Test PTV 95 (Dry)/90 (Wet) (EN 16165:2021): Wet/dry pendulum values ≥90/95 confirm moisture-independent slip resistance.

(3) Elastic Modulus 2.32×10³ MPa (ASTM D6109-24): High-elasticity substrates absorb 83% of impact energy, reducing injury risks during falls.

(4) Load-Bearing Capacity 800kg/m²: Honeycomb support layer design prevents deformation-related accidents.

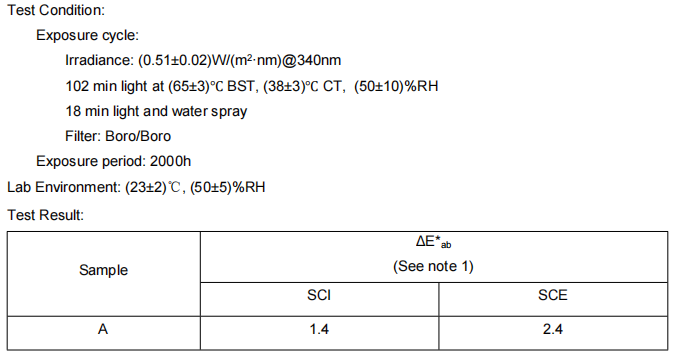

(5) UV Stability: Post-xenon aging color difference ΔE*ab ≤2.4 (ISO 4892-2:2013/Amd.1:2021) and <8% texture degradation after QUV 3000-hour testing guarantee 10-year performance.

Redefining Safety Standards with Data-Driven Solutions

PVC decking’s anti-slip claims are not marketing rhetoric but engineering achievements validated by R12 ratings, PTV 90+ wet-state scores, and 34° tilt thresholds. Every detail withstands dual validation in labs and real-world conditions.

Request a Custom Solution Today:

Our engineers tailor recommendations based on your climate (humidity, rainfall, usage frequency). Contact us to review original test reports and let scientific data safeguard every step.